tl;dr

I helped design a dual-speed transmission that won first place in our class's design competition.

Overview

As part of an annual Caltech tradition for students enrolled in ME 14, teams are challenged to design and build a transmission that effectively couples the rotational power of a brushed DC motor to a rotating bicycle wheel with a $200 budget and a 2-week design period. We propose our designs during a scheduled preliminary design review (PDR) followed by a detailed design during a critical design review (CDR) as well as submit a bill of materials to purchase hardware components and CAD files and GD&T drawings for manufacturing and assembly by the Caltech MCE machine shop. Assembled transmissions will be coupled to a DC motor and mechanical drivetrain testing assembly and evaluated at the end of the class. Designs are then ranked according to specific criteria in order to choose a winner.

Approach

Designs are assessed based on two criteria: maximum RPM divided by time to 250 RPM. Given these criteria, the obvious choice to maximize our score was a two-stage transmission, with each ratio optimizing one of the two categories. While this is accomplishable with more traditional methods like a planetary gearbox or an actuated shifter, they were not very feasible given the strict $200 budget. Additionally, we did not have shop access or testing capagilities due to COVID restrictions, so implementing something that complex was too risky.

We decided it would be easier (though perhaps still risky on our budget) to achieve two ratios using a dual-clutch system. If the input shaft from the motor spins clockwise, one clutch engages and the other slips, where the former gear train can freely dictate the drivng ratio. If the input shaft spins counter-clockwise, the first clutch slips and the second engages, meaning now the second gear train dictates the driving ratio. Some additional considerations would need to be made, such as verifying that the output direction of rotation remained the same with either configuration, otherwise we would transfer way too much energy back into the motor when switching directions.

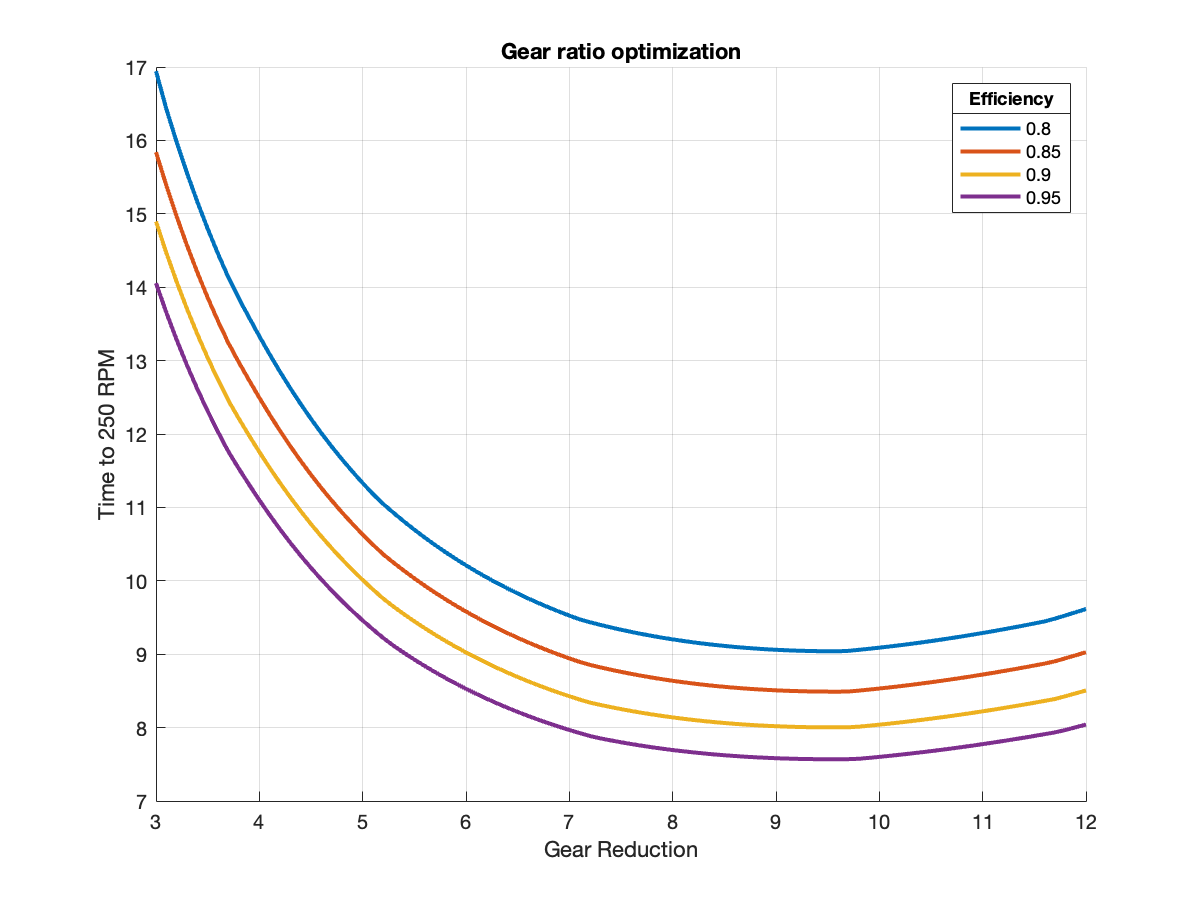

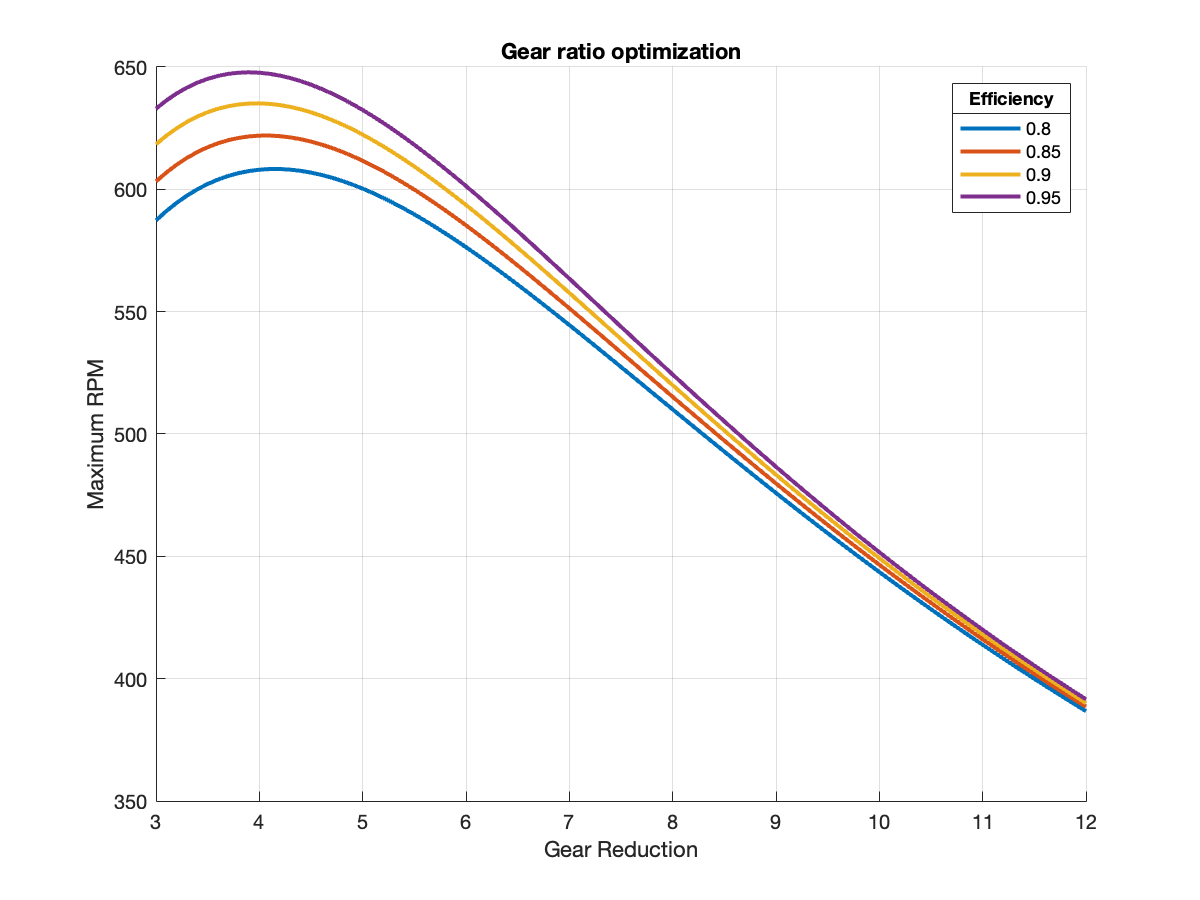

With the high-level approach figured out, the next major task was selecting the two optimal gear ratios. Since we are given the working voltage, motor specs, and approximate dimensions and mass of the bicycle wheel, we can write a rough simulation script in MATLAB that estimates the wheel's rotational intertia and uses it to numerically find the time taken to reach 250 RPM as well as the stable maximum RPM for a range of gear ratios, motor efficiencies, and drag coefficients. We can output some plots to find the optimal ratios for each case:

As one can see in the simulation output above, we found that the ideal reductions for spool-up time and maximum RPM are about 9:1 and 4:1, respectively. It will be pretty difficult to achieve the exact ratios shown above, so we opt to simply get as close as possible with the gears we can find for a reasonable price on SDP/SI.

With the math all figured out, the rest of the design process came down to sourcing parts that fit within our budget, modeling the transmission in CAD, and constructing the necessary GD&T drawings for manufacturing each part. You can find the relevant CAD screenshots and part drawings in our critical design review presentation below.

CDR Slides and Part Drawings

Results

Despite the risks associated with trying something complex on a small budget, we achieved first place in the competition. Our score beat the next-best team by a factor of two. This makes sense given we were the only team to successfully implement a two-stage transmission, as a single-speed design will never be able to optimize both scoring criteria due to torque-speed tradeoffs.

We were incredibly impressed with the performance of our design. Even up to the last moments before the gearbox was placed on the test stand, there was uncertainty as to whether it would perform as expected. There were many unknowns that simply could not be controlled due to the virtual nature of this competition. Comparing to our estimates, we found that the design underperformed on one metric (max RPM) and over performed on the other (time to 250 RPM). Our predicted spool-up time was around 10 seconds, while our gearbox actually achieved this in 5.7 seconds. However, our maximum speed was only about 500 RPM versus the simulated 600 RPM. The discrepancy in simulation is likely due to underestimating the drag force on the wheel, but there was not much more we could have done without access to proper pre-competition testing.

I was overall very pleased with our showing, and really enjoyed the class! I would highly recommend this to anyone exploring the Mechanical Engineering curriculum at Caltech, or just wants a small but fundamentals-packed design challenge.